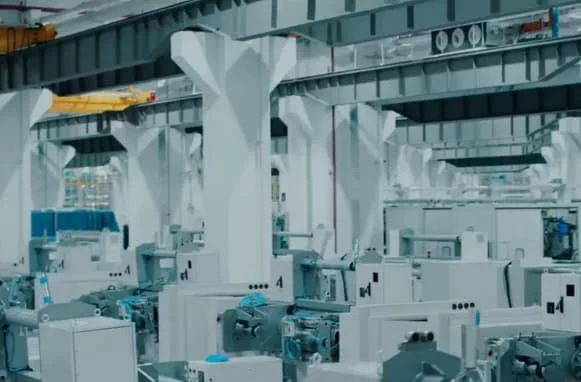

Efficiency and accuracy are critical in the production of solid state batteries. Enter LEAD, a trailblazing brand that is transforming the industry with its state-of-the-art dry electrode coating equipment. This cutting-edge machinery is designed to provide customers with unparalleled quality and speed, boasting a thickness uniformity controlled ≤±2μm. With impressive coating speeds exceeding 80m/min for anodes and over 50m/min for cathodes, LEAD’s equipment is setting new standards in the field.

Unmatched Precision and Speed

LEAD’s dry electrode coating equipment stands out for its exceptional precision and speed. With a focus on delivering superior results, the machinery ensures a thickness uniformity controlled within ≤±2μm, guaranteeing consistent and reliable performance. Operating at speeds surpassing 80m/min for anodes and 50m/min for cathodes, LEAD’s equipment enables swift and efficient production processes, optimizing manufacturing workflows for solid state battery production.

Comprehensive Solution for Smart Manufacturing Companies

LEAD offers a comprehensive solution for smart manufacturing companies seeking to enhance their production capabilities. Specializing in smart solid state battery manufacturing equipment, LEAD provides a full line of equipment for battery cell production, packaging, and testing. This holistic approach streamlines operations, ensuring a seamless and integrated manufacturing process for maximum efficiency and productivity.

Conclusion:

In conclusion, LEAD’s dry electrode coating equipment represents an innovator in the world of solid state battery manufacturing. With a focus on precision, speed, and innovation, LEAD is at the forefront of revolutionizing the industry. For smart manufacturing companies looking to elevate their production capabilities, LEAD offers a complete solution that paves the way for success in the rapidly evolving landscape of battery manufacturing.