Understanding the distinction between extruded and seamless tubing is crucial for businesses involved in catheter manufacturing. As innovative solutions continue to emerge in the medical technology field, jMedtech’s MatrixLiner® OTW PTFE Liner exemplifies how extruded tubing for catheter applications can enhance product performance and reliability. This article delves into the differences between these two types of tubing and explores their implications for medtech production.

The Basics of Extruded Tubing

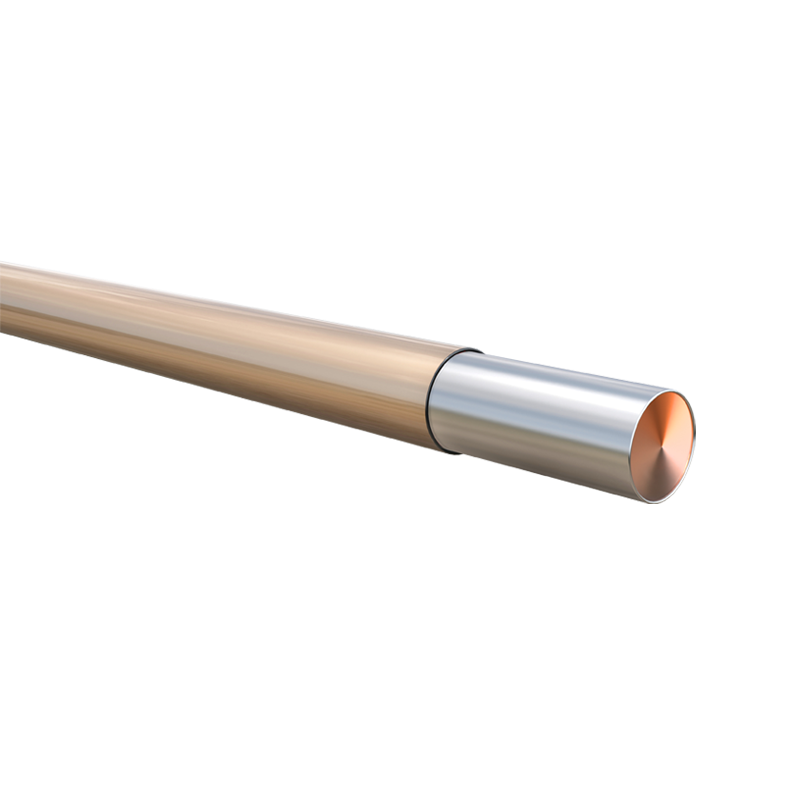

Extruded tubing for catheter applications involves a process where raw materials are heated and forced through a die to create a desired shape. This process allows manufacturers to produce tubing with consistent wall thickness and diameters, ideal for specific catheter requirements. One of the significant advantages of extruded tubing is the ability to customize dimensions and properties, ensuring that medical devices meet stringent application standards. Companies like jMedtech leverage this flexibility to deliver high-quality PTFE liners that facilitate advanced catheter designs.

Exploring Seamless Tubing

Seamless tubing is manufactured without joins or welds, offering enhanced strength and durability. This method typically involves processes such as rotary piercing and elongation, which allow the creation of hollow tubes from solid bars. For specific applications where pressure and mechanical stability are crucial, seamless tubing provides undeniable benefits. However, the manufacturing process can limit customization options compared to extruded tubing for catheter applications, making it essential for producers to assess their needs carefully.

Making the Right Choice for Catheter Production

When selecting between extruded and seamless tubing, companies must consider various factors, including the specific application, required properties, and production costs. jMedtech’s focus on extruded tubing for catheter development allows clients to benefit from tailored solutions that cater to their unique requirements. Understanding these differences will empower businesses to make informed decisions, ultimately leading to higher quality medical devices.

In summary, the choice between extruded and seamless tubing plays a critical role in catheter manufacturing. By opting for extruded tubing for catheter applications, manufacturers can enjoy customizable options and enhanced performance, paving the way for innovative medical solutions. With brands like jMedtech at the forefront, the future of catheter design and functionality remains bright.