AEC-Q100 certification has become the non-negotiable benchmark for ensuring operational amplifiers survive the extreme thermal and mechanical stresses of modern vehicle architectures. As automotive designs transition toward electrified powertrains and autonomous features, the demand for high-precision operational amplifier applications has surged. Unlike consumer electronics, automotive components must operate reliably within a temperature range of -40°C to +150°C, withstand mechanical shock, and possess electrostatic discharge (ESD) protection. Safety-critical systems such as battery management and steering control also require fault-free operation throughout the vehicle’s 15-year lifespan.

Optimizing Operational Amplifier Applications in Automotive Control

Modern vehicles rely on precise feedback loops to manage everything from battery health to steering torque. Engineers must select amplifiers that deliver high slew rates and low voltage operation to match contemporary digital logic levels.

Signal Conditioning in Powertrain and Battery Management

In Electric Vehicles (EVs), the Battery Management System (BMS) requires differential amplification to monitor cell voltages with millivolt accuracy. Rail-to-rail CMOS amplifiers are essential here, as they allow the signal to utilize the full dynamic range of the Analog-to-Digital Converter (ADC), even with low supply voltages like 3.3V or 5V. For instance, in current sensing applications, a high-side current sense amplifier must reject common-mode noise while accurately measuring the voltage drop across a shunt resistor. This precision is critical for calculating the State-of-Charge (SoC) and preventing thermal runaway. Furthermore, operational transconductance amplifier applications are occasionally employed in specific variable-gain stages for sensor linearization, ensuring that data from piezoelectric pressure sensors in the chassis remains accurate under dynamic loads.

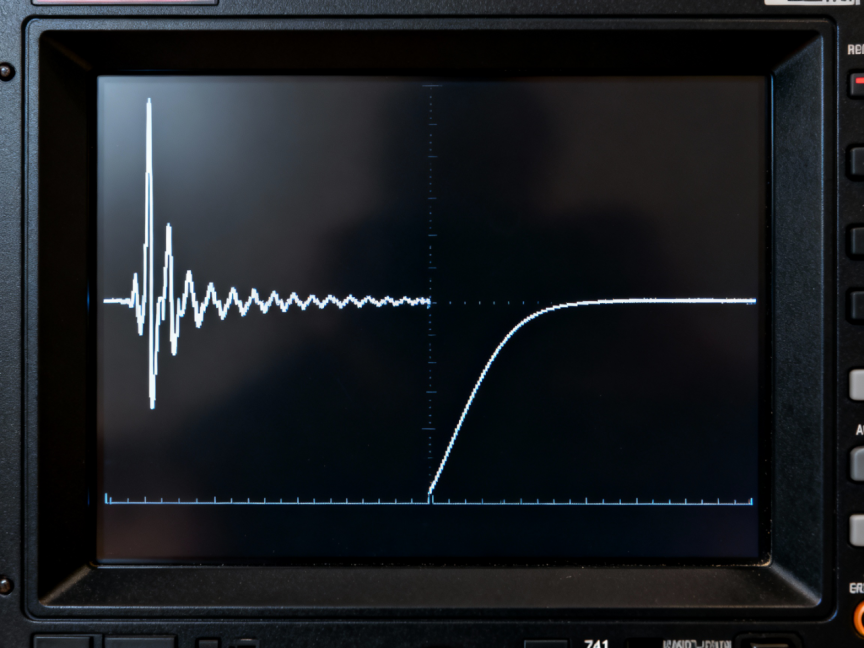

Advantages of CMOS Technology Over Legacy 741 Designs

Traditional 741-type operational amplifiers (op-amps) rely on dual power supplies (e.g., ±15V), resulting in wasted voltage headroom in single-supply (3.3V/5V) automotive systems. Their low slew rate (approximately 0.5 V/μs) and limited input/output swing lead to poor signal integrity, making them unsuitable for the precision requirements of fast transient applications such as electronic power steering. Furthermore, their nanoampere-level bias current introduces significant errors when connected to high-impedance sensors. In contrast, modern CMOS-based op-amps feature rail-to-rail input/output (RRIO) capability, fully utilizing the power supply voltage range and maximizing analog-to-digital converter (ADC) resolution, which is crucial for millivolt-level precision applications such as battery cell monitoring. Their picoampere-level ultra-low bias current minimizes drift and errors in high-impedance sensor interfaces, while slew rates exceeding 10 V/μs support the real-time response required for motor control and feedback loops. Combined with low power consumption, they are more suitable for battery-dependent systems such as electric vehicles and auxiliary modules.

Ensuring Durability with AEC-Q100 Certification Standards

Reliability in automotive electronics is governed by the AEC-Q100 standard, which defines a series of stress tests to predict component lifespan. Without this certification, amplifiers risk premature failure due to harsh environmental conditions.

Temperature Grades and Mechanical Stress Resistance

AEC-Q100 classifies components into temperature grades based on their deployment zone. Grade 0 components, designed for under-hood applications, must withstand ambient temperatures up to +150°C, while Grade 1 is suitable for transmission controllers up to +125°C. Beyond temperature, operational amplifiers design and applications for cars must account for mechanical shock. Vibration testing ensures that the internal wire bonds and die attach materials do not fracture during years of driving on rough terrain. Engineers reviewing operational amplifier applications pdf datasheets must verify that the component has passed temperature cycling tests, typically involving hundreds of cycles between temperature extremes, to guarantee package integrity over a 15-year vehicle lifespan.

Electrostatic Discharge (ESD) and Latch-Up Immunity

Automotive assembly lines and operation in dry environments expose components to high-voltage static electricity. AEC-Q100 mandates rigorous Electrostatic Discharge (ESD) testing, including the Human Body Model (HBM) and Charged Device Model (CDM). A passing grade typically requires HBM tolerance of at least 2000V, ensuring the amplifier is not destroyed during manual handling or installation. Furthermore, latch-up immunity is critical; transient voltage spikes from inductive loads (like motors) can trigger a low-impedance path inside the IC, causing burnout. Automotive-grade amplifiers are designed with internal protection structures to prevent latch-up, ensuring the system recovers gracefully from electrical transients without permanent damage.

UniBetter’s Automotive-Grade Solutions

UniBetter specializes in designing highly reliable rail-to-rail CMOS amplifiers/comparators for automotive and industrial environments, featuring:

Precision and Stability: Ultra-low input offset voltage (<1mV) and minimal drift (<1μV/°C) ensure consistent performance.

Configuration Flexibility: Available in single, dual, and quad-channel options with varying bandwidths to suit diverse circuit topologies.

Supply Chain Assurance: Traceability and quality control support long-term production needs.

Conclusion: Enhance Safety and Performance with Modern Op-Amps

Traditional op-amps like the LM741 are no longer sufficient for modern automotive needs. AEC-Q100 certified rail-to-rail CMOS amplifiers offer superior performance in terms of accuracy, durability, and efficiency. By adopting UniBetter solutions, engineers can future-proof electric vehicle and autonomous driving system designs, ensuring compliance with safety standards and optimizing signal integrity in harsh environments.

Please review your existing circuit diagrams and replace outdated op-amps with rail-to-rail CMOS devices to improve reliability and meet AEC-Q100 certification requirements.