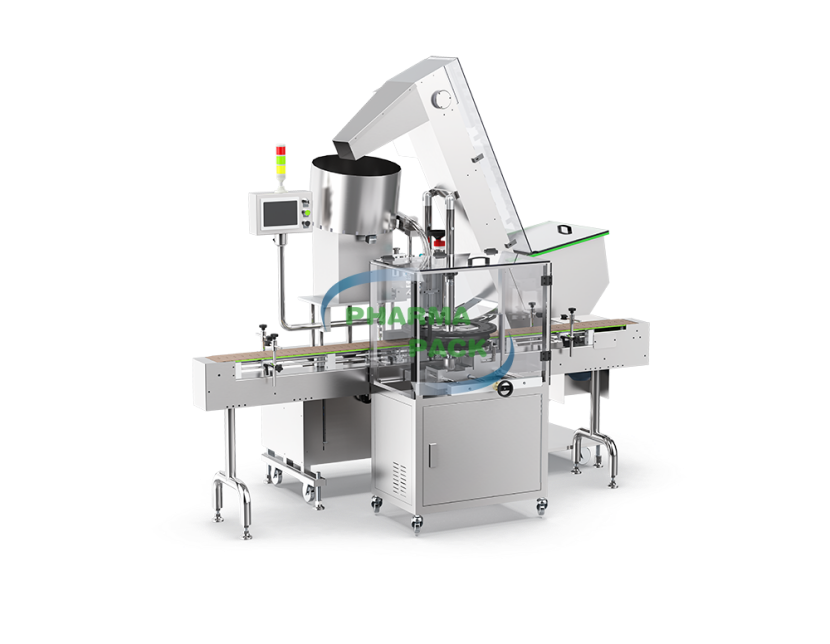

For pharmaceutical companies, optimizing packaging lines is crucial for achieving production goals and maintaining quality standards. Pharmapack specializes in high-speed inserter machines, including desiccant inserters, cotton inserters, and pouch inserters, designed to improve the packaging process for tablets, capsules, and pills in smart bottle packaging line.

Key Features of Pharmapack’s Inserter Machines

Pharmapack’s inserter machines are equipped with advanced technology that ensures accurate and efficient insertion of various components. Whether inserting desiccants for moisture control or cotton for product protection, these machines are built to handle high volumes while maintaining precision. This capability is crucial for sustaining productivity and ensuring that packaging meets stringent quality standards in the smart bottle packaging line.

The design of Pharmapack’s inserters allows for easy integration into existing production lines, making it easier for companies to upgrade equipment without experiencing significant downtime. This flexibility ensures that businesses can enhance operational efficiency and adapt to changing market demands.

Enhancing Productivity and Quality

Integrating high-speed inserter machines into packaging lines reduces manual handling and minimizes errors. This automation boosts productivity while helping to maintain compliance with Good Manufacturing Practices (GMP). Pharmapack’s commitment to quality ensures that each machine is designed to meet industry standards, providing peace of mind for manufacturers.

Conclusion

In summary, Pharmapack‘s high-speed inserter machines offer effective solutions for optimizing pharmaceutical packaging lines, particularly in smart bottle packaging lines. With a focus on precision, efficiency, and compliance, these machines are essential for enhancing tablet, capsule, and pill packaging operations. Explore how Pharmapack can improve packaging processes with innovative inserter technology.