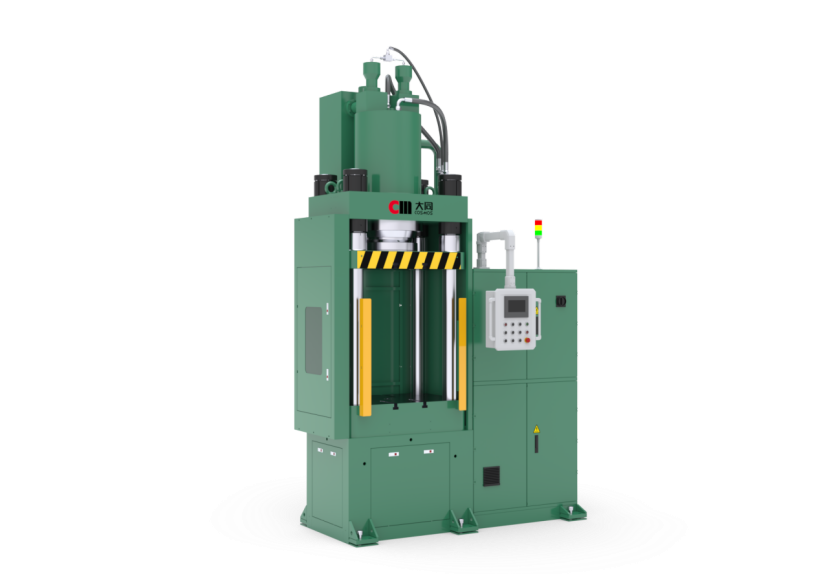

The CMLJ Series Cold Extrusion Hydraulic Press from Cosmos Press is engineered to deliver exceptional performance in various industrial applications. This cold forging press machine combines high precision, energy efficiency, and robust construction to meet the evolving needs of manufacturers.

Structural Integrity and Design

The machine body of the CMLJ series is designed using finite analysis, ensuring optimal strength and rigidity. This structural integrity is essential for maintaining consistent performance, especially under high-pressure conditions. The reasonable design of the press further enhances its operational reliability, making it suitable for extensive use in demanding environments.

Energy Efficiency and Cost Savings

One significant advantage of the Cosmos Press CMLJ series is its ability to save energy significantly. The advanced servo drive system can achieve energy savings of 20-50% when compared to traditional hydraulic presses. This reduction in energy consumption not only lowers operational costs but also aligns with sustainable manufacturing practices.

Improved Production Outcomes

With a production efficiency that is about 35% higher than that of CNC hydraulic presses with conventional motors, the CMLJ series contributes to increased output. This improvement allows manufacturers to optimize their production lines and meet market demands more effectively. The CMLJ series can also function as an extrusion molding machine or a cold forging press machine, depending on the application.

Conclusion

In summary, the CMLJ Series Cold Extrusion Hydraulic Press from Cosmos Press offers multiple performance benefits, including structural integrity, energy efficiency, and improved production outcomes. These features make it an ideal choice for manufacturers seeking to enhance operational capabilities. For more information, interested parties should reach out to Cosmos Press.